Introduction: The Secret Weapon Hiding in Your Warehouse Layout 📦

The most expensive part of warehouse operations isn’t the rent or the equipment—it’s the labor cost associated with travel time. Studies show that up to 50% of a picker’s time is spent walking between locations.

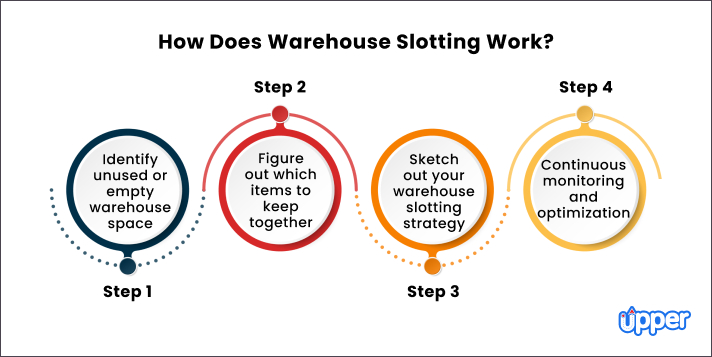

Warehouse slotting is the strategic process of organizing inventory within the warehouse to optimize flow, minimize travel distance, and drastically reduce picking time. Properly implemented slotting strategies can be a secret weapon, boosting your picking efficiency by 30% or more without hiring a single extra staff member.

As logistics specialists focused on high-efficiency fulfillment in competitive markets like Southeast Asia, M2B breaks down the three must-know slotting strategies that you can apply immediately to transform your warehouse performance.

1. ABC Analysis Slotting: Prioritizing Speed Over Everything ⚡

The most fundamental and effective strategy revolves around inventory movement frequency. This method classifies every Stock Keeping Unit (SKU) based on how quickly it is picked and shipped:

- A-Items (Fast Movers): 20% of SKUs that account for 80% of volume.

- B-Items (Medium Movers): 30% of SKUs that account for 15% of volume.

- C-Items (Slow Movers): 50% of SKUs that account for the remaining 5% of volume.

The Strategy: Place all A-Items in the closest and most accessible locations to the packing/shipping dock. This ensures that the most frequently requested items require the shortest travel time, maximizing speed and efficiency for the majority of orders. B and C items are slotted further away.

2. Complementary Slotting (Family Grouping): Cutting Down Stops 👨👩👧👦

Complementary slotting, sometimes called Family Grouping, addresses the common scenario where customers frequently order certain items together (e.g., a phone, a charger, and a protective case).

The Strategy: Instead of slotting these complementary items randomly, they are placed adjacent to one another. When an order requires all three, the picker only needs to stop once, rather than stopping three times across three different aisles. This strategy drastically reduces the total number of “stops” a picker must make per shift, making the order fulfillment process far more fluid.

M2B Insight: This is highly effective for e-commerce, where bundle deals and related accessories are common. Analyzing historical order data is key to identifying these frequently purchased families.

3. Minimum Handling Slotting (The Ergonomics Factor) 💪

While the previous two strategies focus on travel distance and order grouping, Minimum Handling Slotting focuses on protecting your labor force and speeding up the physical act of picking.

The Strategy: This involves placing items based on their size, weight, and handling frequency relative to the picker’s body:

- The Golden Zone: Heavy, bulky, and fast-moving items should be placed between the picker’s waist and shoulder height. This minimizes bending (reducing fatigue) and makes lifting safest.

- Top Racks: Slow-moving or very light items can be placed on higher shelves, requiring less frequent effort.

- Floor/Bottom Racks: Very heavy, slow-moving items can be placed here, minimizing the risk of shoulder/back injury from lifting heavy objects too high.

By reducing strain and injury risk, this strategy improves picker morale, reduces sick leave, and ensures faster picking rates for the longest possible duration.

📰 Current Spotlight: The Automation & Labor Crunch 🤖

The adoption of sophisticated slotting strategies has become even more critical due to the current labor market. As the cost of manual labor increases across Southeast Asia and the competition for reliable warehouse workers intensifies, companies are being forced to optimize every single process before investing in multi-million dollar automation systems. Slotting is the highest-return, lowest-cost optimization available today.

Related News: “Rising Labor Costs Force SEA Fulfillment Centers to Prioritize Slotting Software Over New Conveyors”

Source: Global Supply Chain Insight, Q4 2025 | Read More: [https://www.google.com/search?q=warehouse+labor+shortage+sea+logistics+optimization]

Conclusion: Stop Walking, Start Picking ✅

A well-slotted warehouse is a profitable warehouse. By implementing the ABC Analysis to manage velocity, Complementary Slotting to manage co-occurrence, and Minimum Handling Slotting to manage ergonomics, you can achieve substantial, measurable improvements in your fulfillment efficiency.

You already have the space and the people—now it’s time to optimize the where and the how. M2B specializes in utilizing advanced Warehouse Management System (WMS) capabilities to analyze your inventory data and design a tailored slotting map, guaranteeing your promised 30% efficiency boost.

Ready to Eliminate Hidden Logistics Costs? Get a Free Consultation Today! 🤝

If your picking costs are too high, M2B has the expertise to design and manage a fulfillment strategy that works for your unique inventory profile.

Contact our Logistics Solution Experts:

- Phone / WhatsApp: +62 812 6302 7818

- Email: info@m2b.co.id

- Website: www.m2b.co.id